Contact wheels for belt grinding

Contact wheels are an essential factor for achieving perfect results when belt grinding. Contact wheel and grinding belt need to made compatible: hard X-belts for hard contact wheels, soft J-belts for soft contact wheels. Replacement of ablated coatings is possible with all types.

| Smooth contact wheel | Used with fine grinding, low noise |

|---|---|

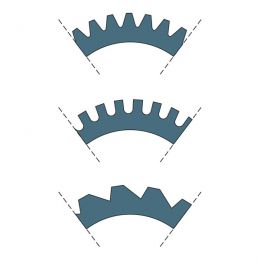

| Ribbed contact wheel | More effective than with smooth wheels. Broad ribbing makes wheel more aggressive, fine ribbing is for fine grinding |

| Possible ribbing | Saw tooth, standard, wolf tooth |

| Hardness of contact wheels | Hardness of contact wheels is measured in "degree" Shore. 20–30 degree Shore = very soft 40 degree Shore = soft 60 degree Shore = medium 80 degree Shore = hard 90 degree Shore = very hart |

Mattieren, Schleifen, Entgraten

Abrasive cloth, economy rolls

Abrasive cloth, economy rolls Abrasive cloth, sheet material

Abrasive cloth, sheet material Abrasive fleece-compact wheels, twisted

Abrasive fleece-compact wheels, twisted Abrasive fleece-flap-cup brush

Abrasive fleece-flap-cup brush Abrasive sleeves

Abrasive sleeves Circular wire brush

Circular wire brush Contact wheel cotton flap

Contact wheel cotton flap Contact wheel Vulkollan foam flaps

Contact wheel Vulkollan foam flaps Contact wheel Vulkollan foam ring, smooth or ribbed

Contact wheel Vulkollan foam ring, smooth or ribbed Contact wheel Vulkollan hard/soft mixed

Contact wheel Vulkollan hard/soft mixed Fibre wheels

Fibre wheels Flap rollers for portable grinders

Flap rollers for portable grinders Flap wheel with plastic core

Flap wheel with plastic core Flap wheel with plastic core – circular embodiment

Flap wheel with plastic core – circular embodiment Flap wheel with shaft

Flap wheel with shaft Flap wheel with sheet metal core – circular embodiment

Flap wheel with sheet metal core – circular embodiment Grinding flap plates

Grinding flap plates Grinding fleece belts

Grinding fleece belts Grinding fleece flap plate

Grinding fleece flap plate Grinding fleece flap wheels

Grinding fleece flap wheels Grinding fleece flap wheels with shaft

Grinding fleece flap wheels with shaft Grinding fleece flap wheels, combined with abrasive cloth

Grinding fleece flap wheels, combined with abrasive cloth Grinding fleece- and handpieces

Grinding fleece- and handpieces Grinding fleece-flap rollers

Grinding fleece-flap rollers Grinding fleece-wave wheels

Grinding fleece-wave wheels Grinding fleece-wheels

Grinding fleece-wheels Grinding ring, V-shaped

Grinding ring, V-shaped Guide pulley for belt grinders

Guide pulley for belt grinders Leather circular wheels

Leather circular wheels Rubber contact wheel, smooth or ribbed

Rubber contact wheel, smooth or ribbed Rubber roller

Rubber roller Rubber roller special manufacture

Rubber roller special manufacture Tynex wheel brush

Tynex wheel brush